Lanxi Cement Plant | 0.7MW/1.505MWh liquid cooling energy storage system

Case introduction

-

Previously, the user-side energy storage project for a cement concrete products enterprise in Lanxi City, Zhejiang Province, constructed by Hua Power, was officially delivered and put into operation! The project has a total capacity of 0.7MW/1.505MWh and uses seven independently developed ‘100kW/215kWh integrated liquid cooling energy storage cabinets.’ Through intelligent energy storage solutions, it helps enterprises optimise their electricity costs and improve production efficiency, injecting new momentum into the green transformation of traditional manufacturing industries.

Bid Farewell to "Off-Peak Production" and Unlock Production Capacity Potential

Related Products

-

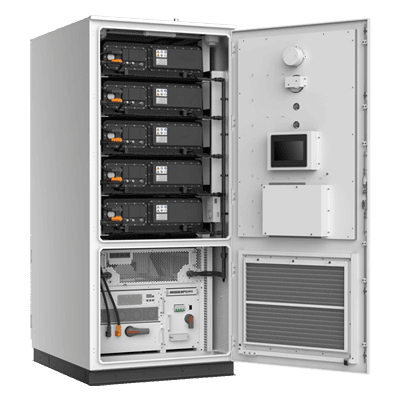

HC233L Liquid Cooling Energy Storage CabinetHC233L Liquid Cooling Energy Storage Cabinet

HC233L Liquid Cooling Energy Storage CabinetHC233L Liquid Cooling Energy Storage Cabinet110kW/233kWh | Highly Efficient Liquid-Cooling

-

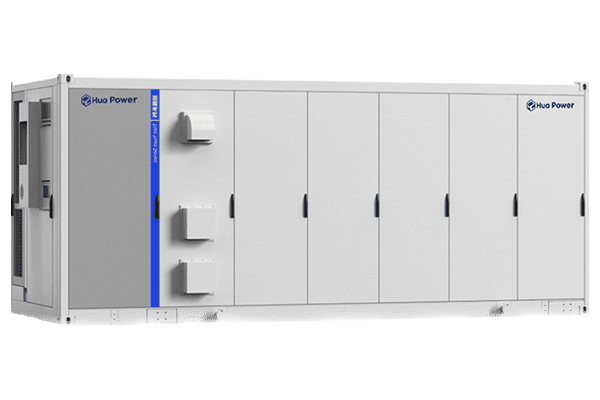

HC522L Liquid Cooling Energy Storage CabinetHC522L Liquid Cooling Energy Storage Cabinet

HC522L Liquid Cooling Energy Storage CabinetHC522L Liquid Cooling Energy Storage Cabinet250kW/522kWh | 314Ah High Energy Density Cell

-

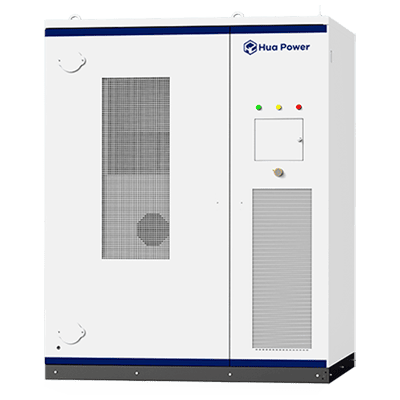

HC261L Liquid Cooling Energy Storage CabinetHC261L Liquid Cooling Energy Storage Cabinet

HC261L Liquid Cooling Energy Storage CabinetHC261L Liquid Cooling Energy Storage Cabinet125kW/261kWh | 314Ah LFP Battery

-

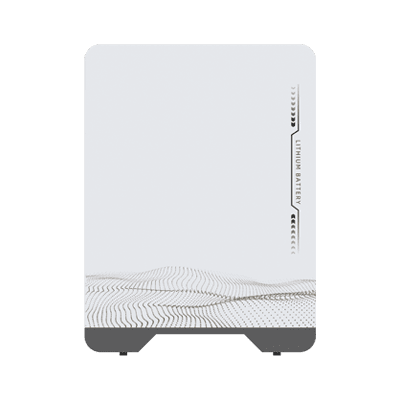

HC1075S Battery ESS Split CabinetHC1075S Battery ESS Split Cabinet

HC1075S Battery ESS Split CabinetHC1075S Battery ESS Split Cabinet500kW/1075kWh | Split Design, Flexible Combination

.jpg)